Why Hydrogen AI Fell Short — and How In-Line Oxygen and Hydrogen Analyzers Are Addressing the Gap

Hydrogen production – advanced in-situ process monitoring with optical analyzers for safe, efficient, and optimized operations.

Real-time in-line oxygen and hydrogen analysis at industrial pressure is addressing a key limitation in hydrogen AI optimization

Global interest in green hydrogen continues to accelerate, with announced electrolyzer projects worldwide now exceeding 500 GW of planned capacity by 2030, according to industry estimates. However, only a small portion of these projects has reached final investment decision or entered construction. Industry analysts increasingly point to operational risk, safety assurance, and long-term controllability as key factors slowing large-scale deployment. At the core of these challenges lies a fundamental issue: the inability, until recently, to perform continuous, in-line measurement of oxygen and hydrogen concentrations under true industrial operating conditions.

Hydrogen production economics are highly sensitive to operating efficiency, asset utilization, and system lifetime. Electricity costs dominate operating expenditure, while electrolyzer stacks and balance-of-plant components represent significant capital investment. As a result, even modest inefficiencies or conservative operating margins can materially impact the levelized cost of hydrogen.

Optimization is therefore a structural requirement rather than a performance enhancement. In industrial electrolysis systems, optimization directly affects:

* electrical efficiency under variable renewable power input

* availability and capacity factor

* degradation rates of electrolyzer stacks

* safety margins applied to balance-of-plant operation

Achieving these objectives requires continuous, reliable insight into the actual state of the process. Artificial intelligence and advanced control techniques have delivered measurable benefits in many industrial sectors. In hydrogen electrolysis, however, their application has often been limited to monitoring or advisory roles. This limitation was not driven by deficiencies in algorithms or computing capability.

Electrolysis simultaneously produces hydrogen and oxygen. These two gases define the process behavior, safety envelope, and long-term degradation mechanisms of the system. Yet many hydrogen facilities lacked continuous, authoritative measurement of hydrogen concentration and oxygen concentration at critical process points.

Existing oxygen analyzer and hydrogen analyzer technologies were generally developed for low-pressure operation or extractive sampling. They relied on pressure reduction, sample conditioning, or off-line analysis. Once pressure is reduced, the measurement no longer represents real process conditions. Fast transients are attenuated, gas crossover effects are diluted, and safety-relevant information is delayed.

As electrolyzer operating pressures increased toward 100 bar, 200 bar, and higher, this limitation became a systemic constraint. Advanced optimization systems were forced to operate on inferred states and proxy variables, limiting their ability to function in closed-loop, safety-critical environments.

Before high-pressure in-line gas analysis

* limited visibility into real-time O₂ and H₂ concentrations

* optimization constrained to advisory or conservative control modes

* wide safety margins imposed to compensate for uncertainty

* slow response to dynamic operating conditions

With high-pressure in-line gas analysis

* direct, continuous measurement of hydrogen and oxygen in the process stream

* optimization bounded by measured physical constraints

* improved response to load changes and transients

* reduced uncertainty without compromising safety

This transition represents a change in system observability rather than an incremental instrument upgrade.

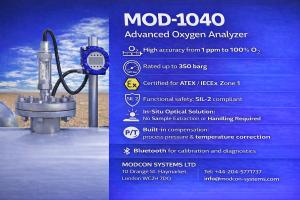

Industrial hydrogen systems impose demanding requirements on measurement technology. Continuous in-line analyzers must operate:

* at pressures up to 350 barg

* in hazardous environments requiring ATEX and IECEx compliance

* within SIL-2 functional safety architectures

* with response times suitable for dynamic control and optimization

Historically, analyzer technologies were generally unable to satisfy all of these requirements simultaneously at industrial scale. The availability of in-situ analyzers designed specifically for these conditions closes this gap.

Modcon’s newly available analyzer architecture combines in-line oxygen analyzers and hydrogen analyzers designed for direct installation on pressurized process piping. The analyzers provide real-time measurement of O₂ and H₂ concentrations without sample extraction, supporting continuous operation under industrial electrolysis conditions.

By restoring reliable observability, this measurement layer enables the practical use of advanced optimization methods, including deep reinforcement learning (DRL). DRL techniques are well suited to managing multi-variable, non-linear processes under changing constraints, provided that the system state is continuously observable and bounded by certified safety limits.

The hydrogen sector has demonstrated technical feasibility at pilot scale. The remaining challenge is long-term, safe, and economical operation at infrastructure scale.

Continuous, high-pressure oxygen and hydrogen analysis supports:

* more confident operation under variable renewable power

* earlier detection of degradation and separation issues

* narrower safety margins without increased risk

* improved confidence for investors, insurers, and regulators

“Stakeholders are increasingly focused on controllability over decades of operation,” Shahnovsky added. “Reliable measurement is what allows optimization strategies to be deployed with confidence at scale.”

About Modcon Systems Ltd

Modcon Systems Ltd is an international provider of industrial process analyzers and advanced optimization solutions serving the energy, chemical, refining, and hydrogen sectors. Founded in 1972, Modcon develops high-performance oxygen analyzers and hydrogen analyzers designed for continuous in-line use in safety-critical industrial environments. The company operates globally, supporting hydrogen projects across Europe, the Americas, the Middle East, and Asia.

Anya Alter

Modcon Systems Ltd.

+44 20 4577 1737

email us here

Visit us on social media:

LinkedIn

YouTube

In-situ Oxygen and Hydrogen Analyzers in Electrolyzers

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.